Product Description

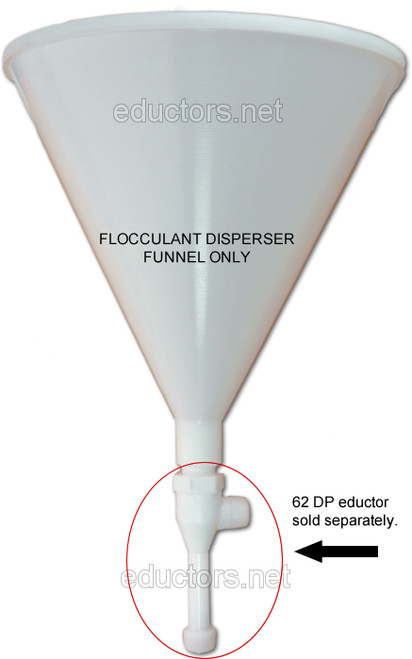

Penberthy Model 62DP Flocculant Disperser is used when powder must be combined with water to create the perfect mix of chemical concentrations. Dispersers can effectively wet 2.27 kg (5 lb) of powder for every 37.8 to 56.7 L (10 to 15 gal.) of water supplied to the unit, resulting in a 4 to 6% concentration of flocculant in the water. This mixture must then be mixed thoroughly with additional water until the powder is dissolved completely and the desired solution concentration obtained. Water supply pressures from 20 to 100 psig (1.37 to 6.89 barg) can be used.

The Penberthy Model 62DP Flocculant Disperser is a ‘small job’ device and operates in a similar manner to a ring jet; the nozzle having the same basic characteristics.

WATER FLOW RATE IN GPM

| PIPE SIZE | WATER SUPPLY PRESSURE AT INLET | ||||

| 20 (PSI) | 40 (PSI) | 60 (PSI) | 80 (PSI) | 100 (PSI) | |

| 3/4" | 8 (GPM) | 12 (GPM) | 15 (GPM) | 17 (GPM) | 20 (GPM) |

SPECIFICATIONS

The Penberthy Model 62DP Flocculant Disperser & funnel are made from DELRIN®. DELRIN® is a crystalline plastic which offers an excellent balance of properties that bridge the gap between metals and plastics. DELRIN® possesses high tensile strength, creep resistance and toughness. It also exhibits low moisture absorption. It is chemically resistant to hydrocarbons, solvents and neutral chemicals. These properties along with its fatigue endurance make DELRIN® ideal for many industrial applications.

DELRIN® construction offers:

- Good dimensional stability

- Low moisture absorption

- DELRIN® can operate in wet environments with little effect on performance or dimensions.

- Excellent machinability

- High fatigue endurance

- High strength and stiffness properties

- Superior impact and creep resistance

- Chemical resistance to fuels and solvents

- Natural grade is FDA, NSF and USDA compliant

- Good wear and abrasion properties with its low coefficient of friction and hard and resilient surface it is the material of choice in many wear applications.